Underground Bulk Tank (UPSS) Leak Detection and Gauging Retrofits

Diesel Tank Leak Detection Systems

Protect your site and meet compliance requirements with advanced leak detection technology.

Diesel tank leak detection systems provide early warning of fuel loss, protecting the environment, reducing remediation costs, and helping meet strict regulatory obligations under the NSW Protection of the Environment Operations (Underground Petroleum Storage Systems) Regulation 2019 and similar standards nationally. Leak detection is mandatory for most underground systems and highly recommended for aboveground facilities handling large volumes.

We supply, install, and maintain a range of leak detection technologies including:

✅ Continuous monitoring systems

✅ Interstitial monitoring

✅ Electronic sensors

✅ Automatic tank gauging systems

With full commissioning and calibration services, we ensure that detection systems meet Australian regulatory requirements and provide peace of mind.

EPA VICTORIA IS INCREASING THEIR FOCUS ON UNDERGROUND PETROLEUM STORAGE SYSTEMS (UPSS) TO ENSURE THAT THERE ARE NO NEGATIVE ENVIRONMENTAL IMPACTS EITHER FROM THE DEGRADATION OF THE TANK VESSEL OR ASSOCIATED FUEL LINES.

TO ASSIST ASSET OWNERS & FM’S EPA VICTORIA HAVE PUBLISHED A COMPREHENSIVE DOCUMENT

888.4: The design, installation and management requirements for underground petroleum storage systems (UPSS).

https://www.epa.vic.gov.au/about-epa/publications/888-4

WHAT IT CONTAINS

Leakage from Underground Petroleum Storage Systems (UPSS) is a significant problem within the petroleum industry. This problem is known to have environmental and safety implications. Improved working practices and a higher level of performance for UPSS are necessary to ensure protection of people, property and the environment. This guideline has been developed in response to concerns about leakage from UPSS, and the need for clear and comprehensive guidance to owners/operators on the level of performance required for UPSS. This replaces publication 888.3, issued July 2014.

Underground Bulk Tank (UPSS) Leak Detection and Gauging Retrofits

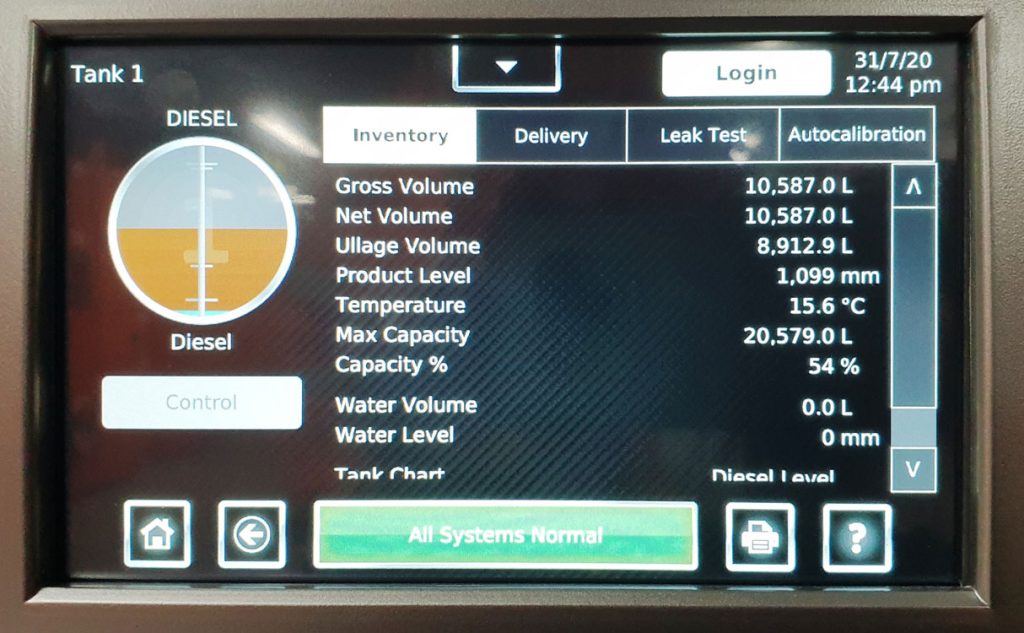

Sinelec now offers retrofitting of automatic leak detection and high-accuracy gauging systems for underground UPSS diesel tanks. These systems provide real-time fuel capacity monitoring and issue alarms in response to any fuel level changes that cannot be attributed to the operation of diesel generator equipment.

Our high-precision technology, sourced from the USA, meets the EPA Victoria leak detection requirements outlined in the 888.4 guidelines, ensuring compliance and reliability.

As part of our installation process, Sinelec provides the following:

- Supply of Tank Monitor Front End – Includes a retrofitted probe within the tank sensing furl level and water ingress. The automatic tank gauge provides inventory reconciliation, auto-calibration, and an accuracy of ±0.1%. Features include an LCD display, audible alarms, and LED indicators.

- Installation of a custom-made measuring probe – Fits into a 2″ or 4″ socket on the manway lid.

- Electrical connections to the tank – Requires suitable cabling from the tank monitor front end to the probe within the turret area, with connections housed in appropriate junction boxes.

- Calibration of the monitor – Custom-calibrated to suit the specific tank vessel and shape. Low and high-level alarm settings are programmed to match client requirements.

- Client BMS interface via Ethernet – Enables customers to create automated tank logging and generate real-time fuel manifests with weekly emails. This data can be used to trigger timely fuel replenishment to ensure continuous operation.

The leak detection system can automate an alert to site owners or FM ‘S